Intralogistics

Download

Submit a request

Sistemi di alimentazione da terra

Shelters

Introduction

Green Solutions for Ports of the Future: Onshore Electrical Power for Eco-Friendly Ships

The auxiliary engines powered by ships in port produce a significant amount of pollutants, including SOx, NOx, CO2 emissions, particulate discharge, and contribute to increased noise levels and vibrations. Considering the implementation of ECA regulations for SOx and the MRV regulation for CO2 emissions, solutions are needed to enhance sustainability in ports.

In recent years, systems for onshore electrical power supply to ships have been introduced to make the presence of ships in ports more sustainable. Onshore power to ship is a key element for port sustainability, aiming to reduce emissions from ships while berthed in ports.

Onshore power supply to ships is a straightforward solution where the ship is essentially connected to an onshore power source. The ship’s power load is transferred to the onshore electrical supply without interrupting onboard services, and emissions in the surrounding environment are eliminated.

This technology holds significant economic and environmental benefits. In addition to reducing pollution, noise, and vibrations in ports, it also results in lower operating costs for shipowners. Such power supply systems, which have been recently introduced, are fundamentally composed of fixed systems to which the ship is connected via a cable.

Innovative Technology to Reduce Pollutant Emissions and Enhance Port Sustainability

MPS Engineering goes beyond with an onboard integrated system for both shore-to-ship and ship-to-shore thanks to the know-how acquired over the years related to:

- Medium Voltage and Low Voltage Systems

- Fire Detection Systems

- Telecommunication Systems for Voice and Data

- Containerized Electrical Transformer Cabins

- Computer Numerical Control Machines

- Supervision and Automation Software

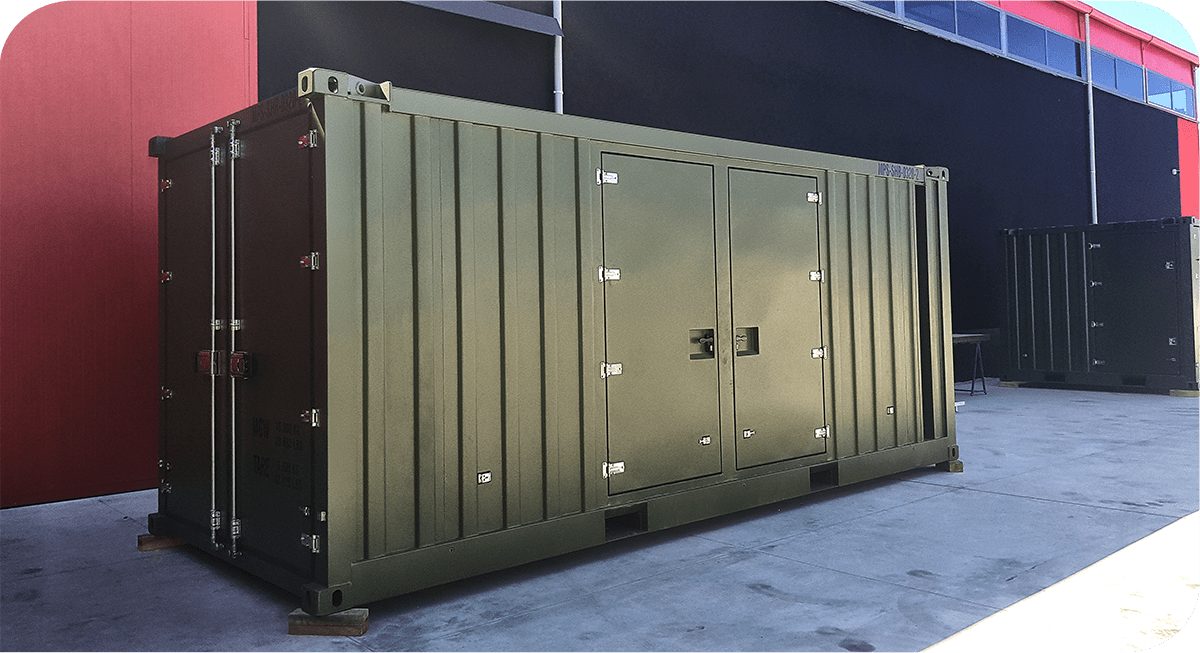

This solution allows both powering a ship using onshore facilities and providing electricity to land utilities using the ship’s onboard systems. For instance, it can provide electrical power to areas lacking it onshore or support a base camp in case of a natural disaster. Another distinctive feature of this system, in addition to the bidirectional capability described above, is its ease of transport and commissioning, as everything is housed within three DNV 2.7.1 certified OFFSHORE containers.

Everything needed to put the system into operation is contained within the containers, including interconnection cables. One of the shelters is equipped with motorized and automatic cable winders, allowing interconnection of the containers up to a distance of 1,000 meters from the ship, all powered during the unwinding and winding phase by an integrated generator in the shelter. In just a few hours, it’s possible to set up a power station from scratch with a capacity of up to 2.0 MVA (equivalent to 1.6 MW).

Secure Energy, High Performance, Sustainable Future.

MPS Engineering’s shelters are characterized by a range of cutting-edge specifications that make them advanced and efficient solutions for electrically powering ships.

Every detail has been carefully designed to ensure high-level performance, sustainability, and safety in the port and maritime environment. These unique features make our shelters an ideal choice for the naval industry.

DNV 2.7.1 CERTIFIED CONTAINERS for offshore and high-sea transport.

ENTIRE EXTERNAL STRUCTURE CONSTRUCTED FROM AISI 316L STAINLESS STEEL with a marine environment suitable paint cycle to minimize the risk of corrosion in a maritime setting.

IP65 CERTIFIED CONTAINERS equipped with a closed-cycle cooling and dehumidification system to prevent the introduction of potentially corrosive external air.

CONTAINERS PROTECTED BY FIRE DETECTION SYSTEM

SUITABLE FOR BOTH 50 HZ AND 60 HZ POWER SUPPLY

FIBER OPTIC COMMUNICATION SYSTEM for Shor to Ship/Ship to Shore data transfer

SUPERVISION SYSTEM that centrally manages all equipment and systems through PLCs; HMI panels display switch statuses, alarms, and information from the MT network and UPS.

HIGH-EFFICIENCY TRANSFORMERS

Innovative Energy Connections: MPS Protects the Seas.

The MPS Engineering system is carefully designed to provide a comprehensive and efficient solution for the electrical power supply of ships.

It consists of 4 containers, each with a specific role to ensure optimal operation and proper connection between the ship and the shore. This modular configuration allows for a flexible and versatile infrastructure, suitable for various needs and types of vessels, contributing to high performance, safety, and sustainability in the port and maritime environment.

The system consists of:

SHELTER “A” Medium Voltage / Low Voltage Transformer Electrical Cabinet

SHELTER “B” Medium Voltage / Low Voltage Transformer Electrical Cabinet

SHELTER “C” It contains the 3-core interconnection cable 6/8 kV

SHELTER “D” Electrical cabin with MT/MT sockets for connection with the LHD unit

| Operating frequency: 50/60 Hz | 50/60 Hz |

| Maximum rated power | 2 MVA (1,6 MW) |

| Container size | 20’ ISO (Shelter A, B, C) 10’ ISO (Shelter D) |

| Container weight | 14.720 kg (Shelter A) 17.040 kg (Shelter B) 19.850 kg (Shelter C) 6.088 kg (Shelter D) |

| Structure | AISI 316L steel |

| Painting | C5-M highly corrosive marine environments RAL 6003 |

| Degree of protection | IP 65 |

| IN/OUT voltages | 0,69/6,0-8,0 kV (Shelter A) 6,0-8,0/0,4-0,69 kV (Shelter B) 0,4 kV (Shelter C) 6,0/0,4 kV (Shelter D) |

| Auxiliary voltages | 110 Vdc da UPS for internal protections 24 Vdc for cable reel motorization |

| Total length of MT interconnection cable | 1.000 m |

| MT cable diameter | 80 m |

| MT Cable laying speed | Up to 4 km/h |