Intralogistics

Submit a request

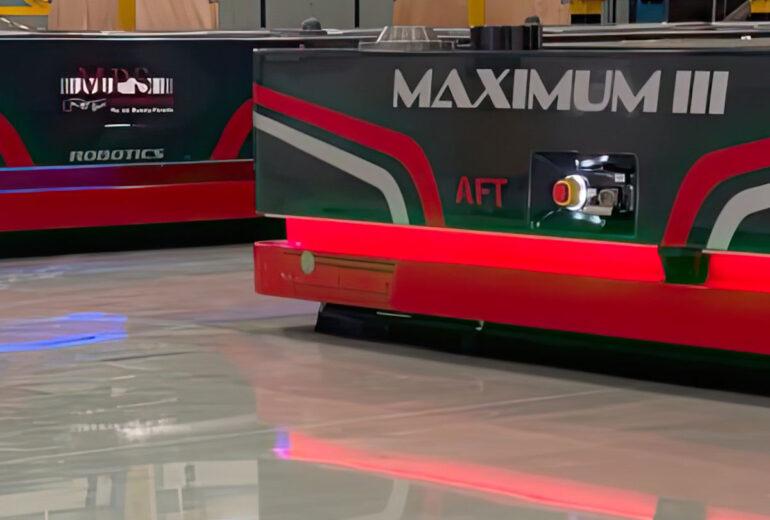

Automated guided vehicles (AGV - AMR)

Autonomous vehicles that revolutionize transportation and transform logistics

MPS Engineering offers advanced solutions for autonomous handling and transportation, including both AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots). These autonomous vehicles represent a turning point in the logistics sector, enhancing operational efficiency and productivity.

MPS Engineering’s AGVs, with their ability to navigate along predefined paths using magnetic signals, provide a reliable option for internal material transportation. They are ideal for applications where the work environment is well-structured and predictable. AGVs can be programmed to perform various handling tasks, such as transporting goods or distributing stock within a warehouse.

Our AMRs are highly versatile autonomous vehicles that utilize cutting-edge technologies such as sensors, cameras, and artificial intelligence algorithms to navigate autonomously in unstructured environments. AMRs can adapt to the dynamics of a continuously changing work environment, making autonomous decisions on navigation and optimizing their routes in real-time. This flexibility allows them to be employed in a wide range of logistics applications, including material transportation, goods delivery, and optimization of storage spaces.

Both our AGV and AMR systems share the goal of automating and improving material handling and transportation processes. Both solutions offer significant benefits, such as increased efficiency, reduced human errors, and improved resource utilization. Additionally, both systems can be integrated with existing computer systems for centralized management and monitoring.

Our company is committed to providing tailored solutions to meet the specific needs of our customers, offering a comprehensive range of AGV and AMR solutions that can be customized to fit different work environments and logistics applications. We take pride in offering cutting-edge technologies that enable our customers to optimize their operations and remain competitive in the ever-evolving logistics market.

Achievement of the goal.

The AGV and AMR systems developed by MPS Engineering allow for the following:

- Increase productivity by eliminating downtime, thanks to optimal 24/7 operation.

- Reduce the need for labor by eliminating the requirement to find workers for repetitive and unappealing tasks.

- Reduce product damage by replacing conventional carts.

- Improve speed and precision of positioning with automatic movement of products between various stations, making the production flow smooth.

- Improve safety by eliminating forklift-related accidents caused by human errors.

- Increase flexibility through interfaces with a variety of stands, automation, and production operations.

- Function as an automatic storage and retrieval system (AS/RS).